Switchgear system design at the click of a button

EPLAN Electric P8 and EPLAN Pro Panel are vital for providing error-free design results and for using schematics, e.g. for the documentation as well as for the commissioning phases.

How long does it take to plan and receive a quote for a switchgear system? Whatever the answer, with EPOS the process is quicker than ever before. The online portal developed by Hell GmbH & Co. KG enables switchgear systems to be designed in a configurator at the click of a mouse. Schematics and production plans as well as cost calculations are generated automatically. EPLAN Electric P8 and EPLAN Pro Panel are the source of the system. From a user's view point, working with EPOS is astonishingly easy: after register-ing at the homepage www.hell-epos.de, preconfigured components such as sen-sors, actuators, ventilators, etc., can be selected as required and added to the con-figuration at the click of a button. The user can then define fields and systems, which in turn can be copied and moved. Construction templates and customised components can also be integrated. A complete switchgear system is developed quickly and easily, be it a simple distribution board or a multi-span switchgear with complex controllers.

Online tool based on EPLAN

When a user is satisfied with the design, only minutes are required to receive plausibility confirmation and a complete, standardised schematic ready for down-load. A detailed overview of costs for the switchgear's manufacture is also includ-ed so the item can be ordered directly with a single click at a guaranteed price. Behind the configurator interface, EPLAN Electric P8 and EPLAN Pro Panel is being used for electrical and control cabinet design. These are vital for providing error-free design results and for using schematics, e.g. for the documentation as well as for the commissioning phases.

The basic idea: Simplifying design

To enable Hell's customers to profit directly from this simplified design process was certainly intended but was not the primary goal. Johannes Paschmanns, the company’s technical-commercial director: “We wanted, first and foremost, to au-tomate our own design procedures. We frequently have challenging design pro-jects, especially in building technology and automation, and our staff are too qual-ified to perform repetitive tasks. Our basic idea was that rather than having to seek out template projects or macros, they should be allowed to get on with the truly creative work.” The German-based switchgear specialists provided the organisational requirements by getting all designers working in one team. Standards for electrical engineering were then established and parts data were unified to such an extent that they could serve as a basis for automated electrical and switchgear engineering.

Investing time in maintaining data

To this day, one employee is exclusively responsible for maintaining parts data. Matthias Hammans: “Data consistency and uniformity is a prerequisite in auto-mated design.” In organizing data, Hell was supported by EPLAN consultants. Hell has worked with CAD solutions from EPLAN for over 30 years, and the engineering systems EPLAN Electric P8 (electrial engineering) and EPLAN Pro Panel (control cabinet engineering) are the basis of the online configuration. These systems take care of the actual “work” of assembly and also provide central data for the production of the control cabinets.

Automation in control cabinet engineering

One reason for the development of EPOS was the desire for greater efficiency in control cabinet engineering. Johannes Paschmanns: “We manufacture the control cabinets in-house and want to continue to do so because we see synergies between design and manufacturing. Yet we want to work as economically as possible and introduce automation here, too. The data generated in EPOS (EPLAN) is therefore used for sheet metal working as well as for wiring.”

Integrated intelligence

The driving force behind the development of the portal has been development director Matthias Hammans who, as a computer scientist, has just the right back-ground for data management. The devil – and indeed the intelligence – is in the detail: “Configuration takes place by component selection. The system automati-cally searches for a logical structure. It links terminals, assigns, defines contact cross-references and ‘knows’, for example, when a pump requires forced activa-tion of a frost monitoring unit.” It is only thanks to this “inbuilt intelligence” that EPOS can produce a complete schematic in EPLAN together with terminal construction plans, a detailed 3D construction plan of the switchgear – and much more. Matthias Hammans: “The plans contain, for example, every wire label, every voltage tap, every connecting point and every jumper setting for the applied component. They incorporate con-tact cross-references and bus addresses and users get complete overview lists of all cables and terminals – down to the very last screw.” And since component prices (over the link to Hell’s ERP system) and the time and labour required for assembly are recorded in the underlying systems, the price for manufacturing the switchgear can likewise be generated automatically.

Substantial time savings

Automating electrical and switchgear design as much as possible has already meant considerable time savings. Johannes Paschmanns: “For wiring alone we are making time savings of 40-60%. Sheet metal working has also speeded up dra-matically. The same applies to drawing up quotes, which we can usually compile in less than half an hour, and, of course, to producing schematics, which takes a matter of minutes. The quality of the planning is of a very high standard and re-working rates are zero. And there are no limits: the system even masters highly complex projects with multiple control cabinet fields and wiring of hundreds of schematic pages.”

Aim: Gaining new customers

After successful internal trial runs, the next logical step was to link customers directly with the configurator via the EPOS-portal. This step has now been com-pleted and our customers are really delighted because they too can now gain time savings. Hell presented the EPOS-portal for the first time at this year’s light+building con-vention. Johannes Paschmanns: “We can now offer control-cabinet users a tool which both considerably simplifies planning and ensures transparency. We are confident that it will help us gain new customers.”

Control Cabinet 4.0 in practice

Hell also take pride in their portal because they are pioneers in the area, setting down principles for the future. Matthias Hammans: “From our perspective the portal is one of the first functional Industry 4.0 systems in the entire sector.” Moreover, it is true to the principles of “Building Information Modeling” (BIM), which are currently the subject of intense discussion amongst architects. Accord-ing to these principles, any alteration in the building planning is automatically effected in all participating specialisms, parts and components. Johannes Paschmanns: “With the combination of possibilities offered by web technology and electrical engineering, we have realised a genuine Industry 4.0 application and a model example for BIM.” And since the portal is based on EPLAN solutions for electrical engineering and control cabinet engineering, EPOS also demonstrates the potential these systems offer for engineering automation. Interested parties can test the demo-version of EPOS free of charge. It can be found at our homepage www.hell-epos.de.

How long does it take to plan and receive a quote for a switchgear system? Whatever the answer, with EPOS the process is quicker than ever before. The online portal developed by Hell GmbH & Co. KG enables switchgear systems to be designed in a configurator at the click of a mouse. Schematics and production plans as well as cost calculations are generated automatically. EPLAN Electric P8 and EPLAN Pro Panel are the source of the system. From a user's view point, working with EPOS is astonishingly easy: after register-ing at the homepage www.hell-epos.de, preconfigured components such as sen-sors, actuators, ventilators, etc., can be selected as required and added to the con-figuration at the click of a button. The user can then define fields and systems, which in turn can be copied and moved. Construction templates and customised components can also be integrated. A complete switchgear system is developed quickly and easily, be it a simple distribution board or a multi-span switchgear with complex controllers.

Online tool based on EPLAN

When a user is satisfied with the design, only minutes are required to receive plausibility confirmation and a complete, standardised schematic ready for down-load. A detailed overview of costs for the switchgear's manufacture is also includ-ed so the item can be ordered directly with a single click at a guaranteed price. Behind the configurator interface, EPLAN Electric P8 and EPLAN Pro Panel is being used for electrical and control cabinet design. These are vital for providing error-free design results and for using schematics, e.g. for the documentation as well as for the commissioning phases.

The basic idea: Simplifying design

To enable Hell's customers to profit directly from this simplified design process was certainly intended but was not the primary goal. Johannes Paschmanns, the company’s technical-commercial director: “We wanted, first and foremost, to au-tomate our own design procedures. We frequently have challenging design pro-jects, especially in building technology and automation, and our staff are too qual-ified to perform repetitive tasks. Our basic idea was that rather than having to seek out template projects or macros, they should be allowed to get on with the truly creative work.” The German-based switchgear specialists provided the organisational requirements by getting all designers working in one team. Standards for electrical engineering were then established and parts data were unified to such an extent that they could serve as a basis for automated electrical and switchgear engineering.

Investing time in maintaining data

To this day, one employee is exclusively responsible for maintaining parts data. Matthias Hammans: “Data consistency and uniformity is a prerequisite in auto-mated design.” In organizing data, Hell was supported by EPLAN consultants. Hell has worked with CAD solutions from EPLAN for over 30 years, and the engineering systems EPLAN Electric P8 (electrial engineering) and EPLAN Pro Panel (control cabinet engineering) are the basis of the online configuration. These systems take care of the actual “work” of assembly and also provide central data for the production of the control cabinets.

Automation in control cabinet engineering

One reason for the development of EPOS was the desire for greater efficiency in control cabinet engineering. Johannes Paschmanns: “We manufacture the control cabinets in-house and want to continue to do so because we see synergies between design and manufacturing. Yet we want to work as economically as possible and introduce automation here, too. The data generated in EPOS (EPLAN) is therefore used for sheet metal working as well as for wiring.”

Integrated intelligence

The driving force behind the development of the portal has been development director Matthias Hammans who, as a computer scientist, has just the right back-ground for data management. The devil – and indeed the intelligence – is in the detail: “Configuration takes place by component selection. The system automati-cally searches for a logical structure. It links terminals, assigns, defines contact cross-references and ‘knows’, for example, when a pump requires forced activa-tion of a frost monitoring unit.” It is only thanks to this “inbuilt intelligence” that EPOS can produce a complete schematic in EPLAN together with terminal construction plans, a detailed 3D construction plan of the switchgear – and much more. Matthias Hammans: “The plans contain, for example, every wire label, every voltage tap, every connecting point and every jumper setting for the applied component. They incorporate con-tact cross-references and bus addresses and users get complete overview lists of all cables and terminals – down to the very last screw.” And since component prices (over the link to Hell’s ERP system) and the time and labour required for assembly are recorded in the underlying systems, the price for manufacturing the switchgear can likewise be generated automatically.

Substantial time savings

Automating electrical and switchgear design as much as possible has already meant considerable time savings. Johannes Paschmanns: “For wiring alone we are making time savings of 40-60%. Sheet metal working has also speeded up dra-matically. The same applies to drawing up quotes, which we can usually compile in less than half an hour, and, of course, to producing schematics, which takes a matter of minutes. The quality of the planning is of a very high standard and re-working rates are zero. And there are no limits: the system even masters highly complex projects with multiple control cabinet fields and wiring of hundreds of schematic pages.”

Aim: Gaining new customers

After successful internal trial runs, the next logical step was to link customers directly with the configurator via the EPOS-portal. This step has now been com-pleted and our customers are really delighted because they too can now gain time savings. Hell presented the EPOS-portal for the first time at this year’s light+building con-vention. Johannes Paschmanns: “We can now offer control-cabinet users a tool which both considerably simplifies planning and ensures transparency. We are confident that it will help us gain new customers.”

Control Cabinet 4.0 in practice

Hell also take pride in their portal because they are pioneers in the area, setting down principles for the future. Matthias Hammans: “From our perspective the portal is one of the first functional Industry 4.0 systems in the entire sector.” Moreover, it is true to the principles of “Building Information Modeling” (BIM), which are currently the subject of intense discussion amongst architects. Accord-ing to these principles, any alteration in the building planning is automatically effected in all participating specialisms, parts and components. Johannes Paschmanns: “With the combination of possibilities offered by web technology and electrical engineering, we have realised a genuine Industry 4.0 application and a model example for BIM.” And since the portal is based on EPLAN solutions for electrical engineering and control cabinet engineering, EPOS also demonstrates the potential these systems offer for engineering automation. Interested parties can test the demo-version of EPOS free of charge. It can be found at our homepage www.hell-epos.de.

Matthias Hammans, Director of Development (left) and Johannes Paschmanns, Technical and Commercial Director (right) of Hell GmbH & Co. KG, Krefeld.

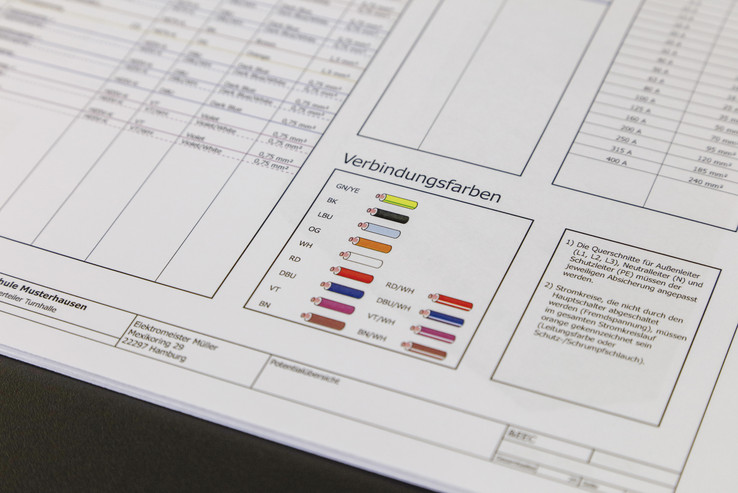

EPOS also simplifies and standardises control cabinet engineering at the shop floor level: personnel are guided step by step through the sequence of operations.

Matthias Hammans, Director of Development (left) and Johannes Paschmanns, Technical and Commercial Director (right) of Hell GmbH & Co. KG, Krefeld.

EPOS also simplifies and standardises control cabinet engineering at the shop floor level: personnel are guided step by step through the sequence of operations.