An organised flow of materials – and well structured planning

Four completely new warehouse sites with around 40 automated small-parts systems, approximately 200 control cabinets, more than 3,000 motors and in excess of 14,000 sensors/actuators are just some of the key features of a major electrical planning project.

Four completely new warehouse sites with around 40 automated small-parts systems, approximately 200 control cabinets, more than 3,000 motors and in excess of 14,000 sensors/actuators: just some of the key features of a major electrical planning project that the Siemens Division "Process Industries and Drives" has successfully completed for a Lower Bavarian automotive manufacturer. Taking part in the success were EPLAN Electric P8 and EEC One – and the highly structured automation and standardisation of design procedures. A vehicle consists of several thousands of small parts. Parts such as engine blocks, coachwork elements and seats are large but the majority are relatively small. It is a major logistical challenge for manufacturers and suppliers to ensure all the small parts, such as handles, lamps and fasteners, get to the right place in the assembly process. Each factory is therefore equipped with at least one automated small-parts system in which the parts can be stored, picked and accessed precisely according to sequence.

Sophisticated storage automation at 4 locations

A Lower Bavarian automotive manufacturer has re-organised its production logistics and commenced operation of small-parts storage facilities at 4 sites using a total of around 40 automated small-parts systems. Approximately 2,000 containers at each site store and retrieve small parts per hour. Each site has a pre-storage zone for manual depalletizing and picking. The parts required by production are loaded onto tugger train trolleys (Fig. 1). This provides an organised and efficient flow of materials. Each of the four facilities are similarly constructed but each has varying features. They were designed, built and commissioned by the Siemens Division "Process Industries and Drives" – it was a major but typical project for the electrical engineering design company located in Stuttgart. Team leader and engineer Jürgen Göhringer: "We have experience of working on projects requiring in excess of 10,000 design hours". Around 20 electrical designers utilize high-performance ECAD tools and they place a high value on the automation and standardisation of processes: "This requires a lot of preparatory effort. But the effort is worth it because it shortens overall planning times".

More than 200 control cabinets

The outcome of the planning has impressive figures. The complete project includes more than 200 control cabinets and the activation of more than 3,000 motors and 14,000 sensors and actuators. For the largest of the automated small-part systems – at the Lower Bavarian automotive manufacturer Dingolfing site – more than 100 cabinets were designed which included the control of around 1,000 motors and 6,000 sensors. Around 900 input and output assemblies from the Simatic ET200Pro periphery module (Fig. 2) provides Profinet field communications between actuators, sensors and fail-safe control from the Simatic S7 319F.

The first step: standardisation

The first step in working with the customer concerned standardisation. Siemens electrical designer Martin Fritz: "We decided together on one documentation standard – including its design and layout – and defined a standard project. We then produced a sample control cabinet, initially without wiring and then with wiring. The real design work then began only after this sample had been accepted by the customer". Siemens uses EPLAN Electric P8 as the main tool for electrical design at its Stuttgart site. Designer Sabine Graw: "We have already completed several projects using P8 and have thereby been able to gain plenty of experience in project structuring".

Next step: developing macros for 4 facilities

The "planning prior to planning" took more than two months. But Jürgen Göhringer and his team are convinced that this is time well invested: "We are dealing with highly complex systems that must provide high levels of availability. Errors can not be allowed to occur – also during planning and design". The beginning of the actual electrical design involved systematically modularising the individual systems and their components. Martin Fritz: "Using EPLAN Electric P8, we structured the entire project into macros which we specially defined for the customer". The aim was to portray the entire control technology for the automated small-part storage system in as few variants as possible. The result was a "master list" for use by all designers working on the project. This list contains an authoritative selection of usable components along with their technical specifications. Sabine Graw: "We have developed a macro for every sensor, every motor and every ET200 periphery station".

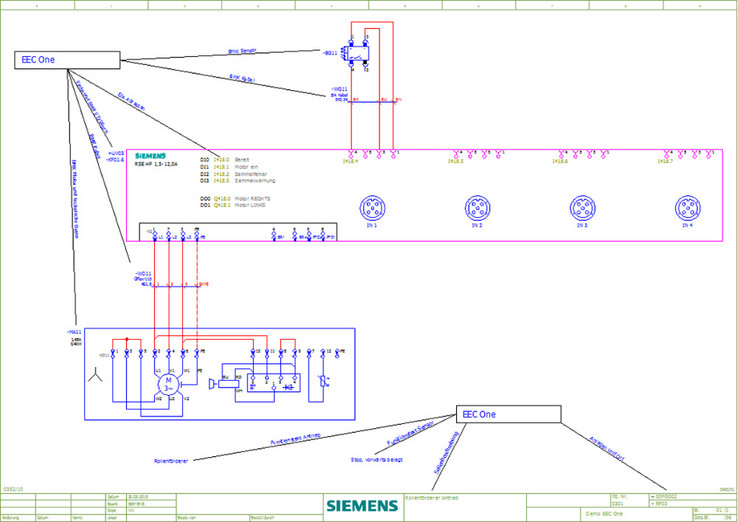

Automated schematic generation using EEC One

The macros are also portrayed as copy lists in EEC One. This software enable the macros to be selected and linked to an Excel interface. The information is sufficient to automatically generate circuit diagrams – this significantly simplifies the work, minimises error rates, and enables fast, virtually automated modifications, e.g. of cable diameters. Jürgen Göhringer: "EEC One is ideal for standardising planning and also speeds up the process because schematics are easy to duplicate or vary". But this requires discipline: "Only two persons may set up a new article within EPLAN. This kind of rule is really important to standardise planning".

Logistical challenge: 10 electrical designers for one project

Up to 10 designers were working simultaneously at Siemens on the design of the automated small-parts storage system – a logistical challenge. The 4 systems at the 4 stations were planned and brought into operation on a time delayed basis. This enabled processes to be optimised as the project developed. All systems are now in operation and running smoothly. This is without doubt a result of planning using tools that enabled far-reaching standardisation and automation.

Conclusion: standardisation saves time

In view of the outcomes, it is of no surprise that the persons responsible are positive about the project. Jürgen Göhringer: "We intentionally set down tight deadlines in the first three months and invested lots of time in standardisation. This time has however been recouped in the electrical design process" . It is important for Siemens managers that "engineering automation" gives engineers the time to use their creativity: "Using EEC One enables us to avoid duplicate work. Without this automation we would have needed more manpower. Major projects could then be completed only with lots of stress because of the extremely high level of coordination effort that would be needed".

Four completely new warehouse sites with around 40 automated small-parts systems, approximately 200 control cabinets, more than 3,000 motors and in excess of 14,000 sensors/actuators: just some of the key features of a major electrical planning project that the Siemens Division "Process Industries and Drives" has successfully completed for a Lower Bavarian automotive manufacturer. Taking part in the success were EPLAN Electric P8 and EEC One – and the highly structured automation and standardisation of design procedures. A vehicle consists of several thousands of small parts. Parts such as engine blocks, coachwork elements and seats are large but the majority are relatively small. It is a major logistical challenge for manufacturers and suppliers to ensure all the small parts, such as handles, lamps and fasteners, get to the right place in the assembly process. Each factory is therefore equipped with at least one automated small-parts system in which the parts can be stored, picked and accessed precisely according to sequence.

Sophisticated storage automation at 4 locations

A Lower Bavarian automotive manufacturer has re-organised its production logistics and commenced operation of small-parts storage facilities at 4 sites using a total of around 40 automated small-parts systems. Approximately 2,000 containers at each site store and retrieve small parts per hour. Each site has a pre-storage zone for manual depalletizing and picking. The parts required by production are loaded onto tugger train trolleys (Fig. 1). This provides an organised and efficient flow of materials. Each of the four facilities are similarly constructed but each has varying features. They were designed, built and commissioned by the Siemens Division "Process Industries and Drives" – it was a major but typical project for the electrical engineering design company located in Stuttgart. Team leader and engineer Jürgen Göhringer: "We have experience of working on projects requiring in excess of 10,000 design hours". Around 20 electrical designers utilize high-performance ECAD tools and they place a high value on the automation and standardisation of processes: "This requires a lot of preparatory effort. But the effort is worth it because it shortens overall planning times".

More than 200 control cabinets

The outcome of the planning has impressive figures. The complete project includes more than 200 control cabinets and the activation of more than 3,000 motors and 14,000 sensors and actuators. For the largest of the automated small-part systems – at the Lower Bavarian automotive manufacturer Dingolfing site – more than 100 cabinets were designed which included the control of around 1,000 motors and 6,000 sensors. Around 900 input and output assemblies from the Simatic ET200Pro periphery module (Fig. 2) provides Profinet field communications between actuators, sensors and fail-safe control from the Simatic S7 319F.

The first step: standardisation

The first step in working with the customer concerned standardisation. Siemens electrical designer Martin Fritz: "We decided together on one documentation standard – including its design and layout – and defined a standard project. We then produced a sample control cabinet, initially without wiring and then with wiring. The real design work then began only after this sample had been accepted by the customer". Siemens uses EPLAN Electric P8 as the main tool for electrical design at its Stuttgart site. Designer Sabine Graw: "We have already completed several projects using P8 and have thereby been able to gain plenty of experience in project structuring".

Next step: developing macros for 4 facilities

The "planning prior to planning" took more than two months. But Jürgen Göhringer and his team are convinced that this is time well invested: "We are dealing with highly complex systems that must provide high levels of availability. Errors can not be allowed to occur – also during planning and design". The beginning of the actual electrical design involved systematically modularising the individual systems and their components. Martin Fritz: "Using EPLAN Electric P8, we structured the entire project into macros which we specially defined for the customer". The aim was to portray the entire control technology for the automated small-part storage system in as few variants as possible. The result was a "master list" for use by all designers working on the project. This list contains an authoritative selection of usable components along with their technical specifications. Sabine Graw: "We have developed a macro for every sensor, every motor and every ET200 periphery station".

Automated schematic generation using EEC One

The macros are also portrayed as copy lists in EEC One. This software enable the macros to be selected and linked to an Excel interface. The information is sufficient to automatically generate circuit diagrams – this significantly simplifies the work, minimises error rates, and enables fast, virtually automated modifications, e.g. of cable diameters. Jürgen Göhringer: "EEC One is ideal for standardising planning and also speeds up the process because schematics are easy to duplicate or vary". But this requires discipline: "Only two persons may set up a new article within EPLAN. This kind of rule is really important to standardise planning".

Logistical challenge: 10 electrical designers for one project

Up to 10 designers were working simultaneously at Siemens on the design of the automated small-parts storage system – a logistical challenge. The 4 systems at the 4 stations were planned and brought into operation on a time delayed basis. This enabled processes to be optimised as the project developed. All systems are now in operation and running smoothly. This is without doubt a result of planning using tools that enabled far-reaching standardisation and automation.

Conclusion: standardisation saves time

In view of the outcomes, it is of no surprise that the persons responsible are positive about the project. Jürgen Göhringer: "We intentionally set down tight deadlines in the first three months and invested lots of time in standardisation. This time has however been recouped in the electrical design process" . It is important for Siemens managers that "engineering automation" gives engineers the time to use their creativity: "Using EEC One enables us to avoid duplicate work. Without this automation we would have needed more manpower. Major projects could then be completed only with lots of stress because of the extremely high level of coordination effort that would be needed".