Inženjering

Digitalizacija i izrada prototipa povećavaju produktivnost

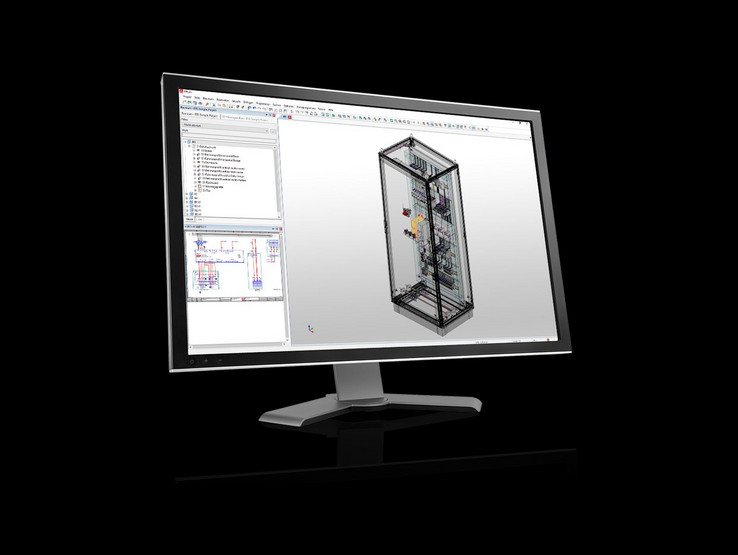

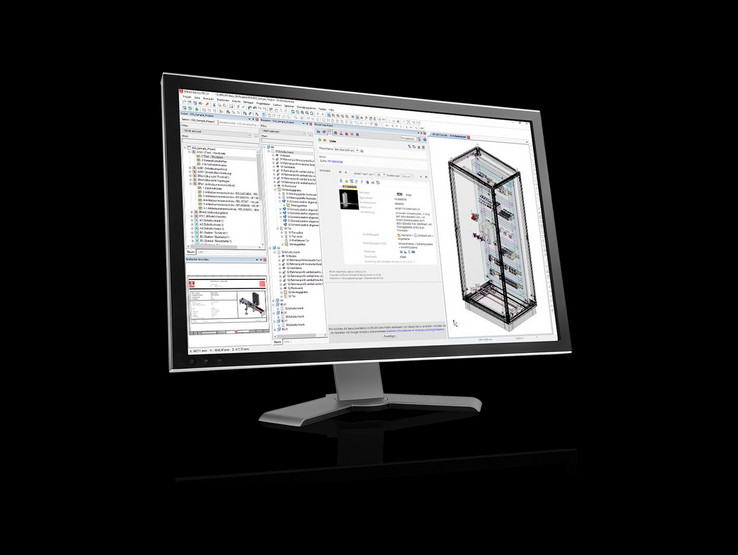

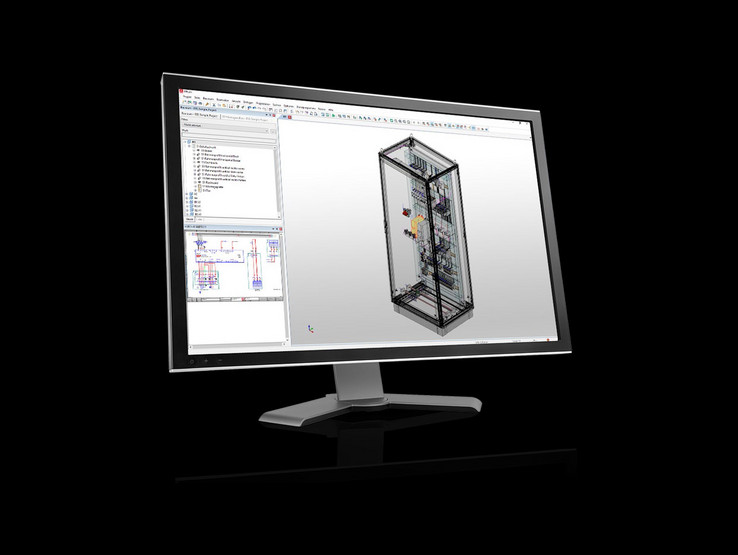

Upravljački ormar se digitalno planira i projektira u inženjerskom odjelu. Softverska EPLAN rješenja savršeno rade zajedno kako bi stvorili središnju bazu podataka za Vaš cijeli proces lanca vrijednosti: korak po korak, digitalni blizanac proizvoda iz stvarnosti stvara se kao dosljedan podatkovni model. Visokokvalitetni 3D podaci prikazuju kućište i dodatke. Ovi podaci su dopunjeni komponentama specifičnim za projekt i informacijama o ožičenju. Kao dio ovog procesa, svi inženjerski podaci dostupni su u centraliziranom okruženju rješenja kojem se također može pristupiti u daljnjim koracima procesa. Na taj se način čak i masovna prilagodba može automatizirati i implementirati na troškovno učinkovit način.

Tehničke specifikacije

Proizvođač ormara i sklopne opreme prima podatke od kupca i potvrđuje ih ovisno o dostupnosti podataka o uređajima, cjelovitosti i prikladnosti za sve naknadne procese, npr. u inženjeringu i pripremi rada. Ako je nužno, podatke je potrebno odgovarajuće pripremiti. Štoviše, određuju se neophodne opcije elektro ormara i povezani dodatni koraci procesa.

EPLAN Data Portal

- Pronađite standardizirane i međunarodno primjenjive podatke o komponentama brzo i jednostavno

- Iskoristite čistu uštedu vremena tijekom projektiranja u usporedbi s ručnim procesima

- Značajno poboljšajte kvalitetu svoje dokumentacije

EPLAN Preplanning

- Držite sve svoje podatke o sustavu, stroju ili zgradi dobro strukturiranima i uvijek vidljivima

- Unaprijed isplanirajte osnovne informacije kao što su podaci o signalima, cjevovodima i kabelima na grafičkoj osnovi za poboljšano snalaženje

- Svo relevantno osoblje ima jednostavan pristup inženjerskim podacima prikupljenim u ranim fazama projekta – i zadržava taj pristup tijekom i nakon projekta

- Korištenje EPLAN Preplanning-a u fazi nuđenja i besprijekoran prijenos podataka u inženjering značajno smanjuje Vaše vrijeme razvoja projekta

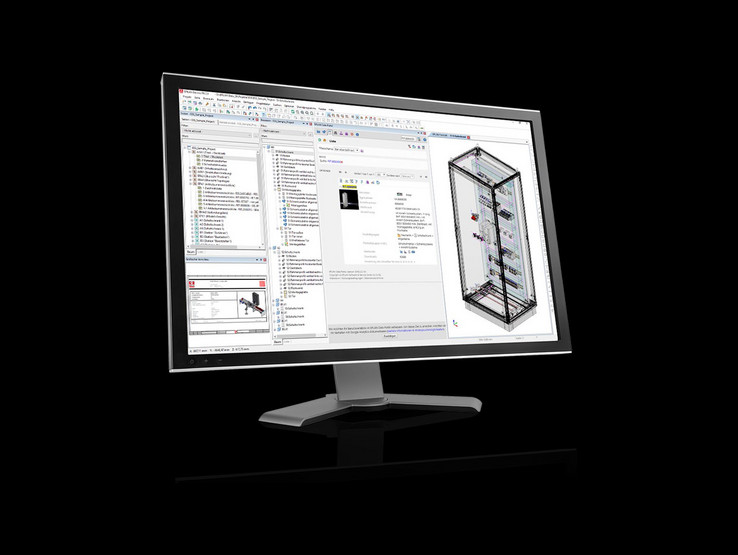

EPLAN Pro Panel

- Od generiranja strujnih shema i rasporeda opreme do proizvodne integracije – dovršite sve zadatke u jednom softverskom paketu

- Pružanjem narudžbenih podataka i opsežnih proizvodnih dokumenata postižete automatizirano opremanje elektro ormara

- Smanjujete vrijeme trajanja i troškove – uz ciljanu razinu kvalitete

- Radite profitabilno – od pojedinačnog projekta u veličini serije 1 pa sve do masovne proizvodnje

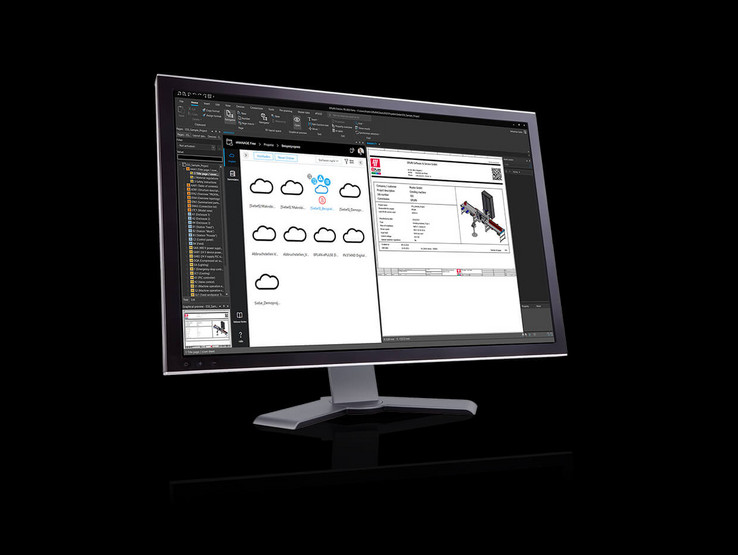

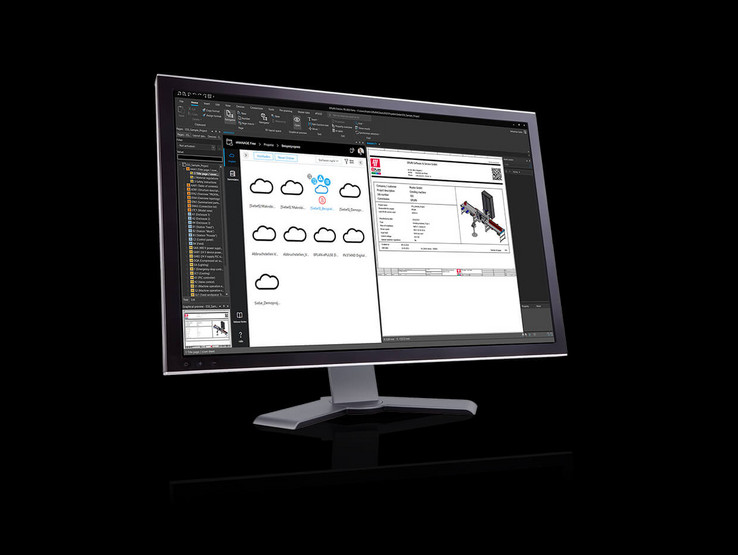

EPLAN eMANAGE

- Središnji pristup Vašim EPLAN projektnim datotekama, matičnim podacima i drugim datotekama duž lanca vrijednosti za sve projektne partnere

- Pobrinite se da svi rade s istom verzijom Vaših projektnih podataka, bilo da su zaposlenici tvrtke ili vanjski projektni partneri

- Zadržite punu kontrolu nad svojim intelektualnim vlasništvom

- Iskoristite sinergijske učinke između različitih EPLAN rješenja jednostavnim prosljeđivanjem podataka o projektu drugim aplikacijama, npr. EPLAN eVIEW

Tehničke konzultacije i projektiranje

Definirana su prikladna rješenja za elektro ormare, potrebnu dodatnu opremu sustava, distribuciju energije kao i grijanje, hlađenje ili kontrolu klime.

Konzultacije lanca vrijednosti

- Rittal stručnjaci rade s kupcima i koriste alat za analizu procesa kako bi identificirali potencijalne dobitke učinkovitosti kroz lanac procesa

- Konzultantske usluge daju praktične preporuke za uštede

RiPanel

- Jednostavno odaberite elektro ormar i dodatke i s lakoćom ga konfigurirajte

- Izrezi i izbušene rupe projektiraju se i vizualiziraju u 3D okruženju u stvarnom vremenu

- Uštedite puno vremena – proizvodni dokumenti i podaci se generiraju automatski na kraju procesa konfiguracije: CAD datoteka za cijelu konfiguraciju, CNC datoteka za jednostavnu strojnu obradu, podaci s konfiguracijama specifičnim za kupca za prosljeđivanje u EPLAN Pro Panel

- Nakon faze projektiranja možete predati upit za konfiguraciju ili je naručiti direktno online

Energetika

- Modularni sustav bez licence osigurava Vam značajno smanjene troškova planiranja, naručivanja i montaže – jednostavno odaberite dodatke i postavite ih na grafiku

- Popisi dijelova i komponenti, tehničke vjerodajnice i dokumentacija generiraju se automatski

- Tehnička podrška dostupna je od strane Rittal-a na zahtjev

EPLAN eMANAGE

- Središnji pristup Vašim EPLAN projektnim datotekama, matičnim podacima i drugim datotekama duž lanca vrijednosti za sve projektne partnere

- Pobrinite se da svi rade s istom verzijom Vaših projektnih podataka, bilo da su zaposlenici tvrtke ili vanjski projektni partneri

- Zadržite punu kontrolu nad svojim intelektualnim vlasništvom

- Iskoristite sinergijske učinke između različitih EPLAN rješenja jednostavnim prosljeđivanjem podataka o projektu drugim aplikacijama, npr. EPLAN eVIEW

Product Functions Design

Schematic design with ECAD software – the entire value chain subsequently benefits from consistent engineering data .

EPLAN Data Portal

- Find standardized and internationally applicable component data quickly and easily

- Benefit from clear time savings during project planning compared to manual processes

- Boost the quality of your documentation significantly

EPLAN Electric P8

- Choose between a graphical, logical or device-based project planning approach to support different working processes

- Auto-connecting allows you to logically connect schematics symbols in no time at all

- Reports such as terminal diagrams, wiring diagrams or bills of materials are generated automatically

- Features for processing bulk data such as "find and replace" and "edit in Excel" accelerate the design process while increasing quality

EPLAN eMANAGE

- Central access to your EPLAN project files, master data and further files along the value chain for all project partners

- Ensure that everyone is working with the same version of your project data, whether company employees or external project partners

- Retain full control over your intellectual property

- Exploit synergy effects between different EPLAN solutions by simply forwarding your project data to other applications, e.g. EPLAN eVIEW

Checking & Correcting

The schematic is checked for conformity to standards, completeness and correctness before it is made available for subsequent processes. This way, errors in subsequent processes, e.g. in the unambiguous designation of components or in the complete description of electrical connections, can be avoided. Ideally, this is done automatically with the support of the ECAD software.

EPLAN Electric P8

- Choose between a graphical, logical or device-based project planning approach to support different working processes

- Auto-connecting allows you to logically connect schematics symbols in no time at all

- Reports such as terminal diagrams, wiring diagrams or bills of materials are generated automatically

- Features for processing bulk data such as "find and replace" and "edit in Excel" accelerate the design process while increasing quality

EPLAN eMANAGE

- Central access to your EPLAN project files, master data and further files along the value chain for all project partners

- Ensure that everyone is working with the same version of your project data, whether company employees or external project partners

- Retain full control over your intellectual property

- Exploit synergy effects between different EPLAN solutions by simply forwarding your project data to other applications, e.g. EPLAN eVIEW

Mechanical Infrastructure

With a view to the customer’s requirements, the location, the environmental conditions and the space required for the installation of the electrical and fluid components specified in the schematic, the appropriate type of enclosure is selected, dimensioned and supplemented with the necessary accessories.

RiPanel

- Simply select enclosure and accessories and configure your new enclosure with ease

- Cut-outs and drilled holes are planned and visualized in 3D in real time

- Save a lot of time – production documents and data are generated automatically at the end of the configuration process: a CAD file for the entire configuration, a CNC file for straightforward machining, data with customer-specific configurations for forwarding to EPLAN Pro Panel

- After the planning stage, you can submit an enquiry for the configuration or order it online directly

EPLAN Data Portal

- Find standardized and internationally applicable component data quickly and easily

- Benefit from clear time savings during project planning compared to manual processes

- Boost the quality of your documentation significantly

EPLAN Pro Panel

- From generating circuit diagrams and assembly layouts to production integration – complete all tasks in a single software package

- By providing order information and comprehensive manufacturing documents, you achieve automated enclosure manufacturing

- You shorten throughput times and costs – at a targeted level of quality

- You work profitably – from an individual project in batch size 1 all the way to volume production

EPLAN eMANAGE

- Central access to your EPLAN project files, master data and further files along the value chain for all project partners

- Ensure that everyone is working with the same version of your project data, whether company employees or external project partners

- Retain full control over your intellectual property

- Exploit synergy effects between different EPLAN solutions by simply forwarding your project data to other applications, e.g. EPLAN eVIEW

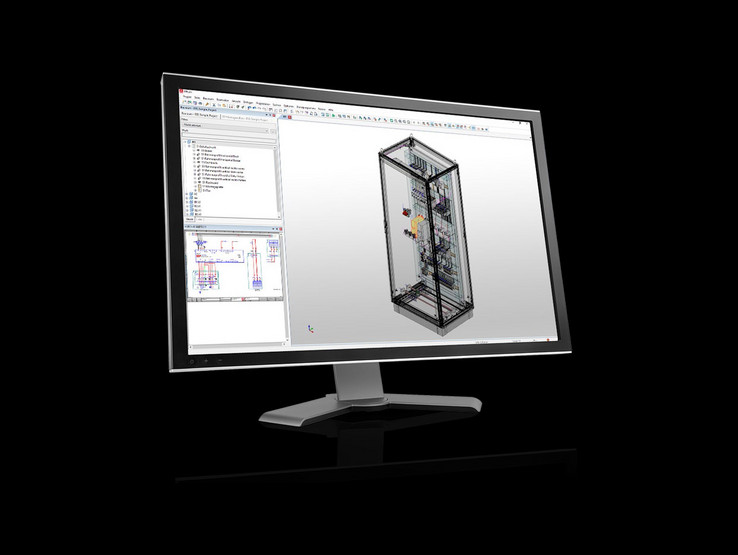

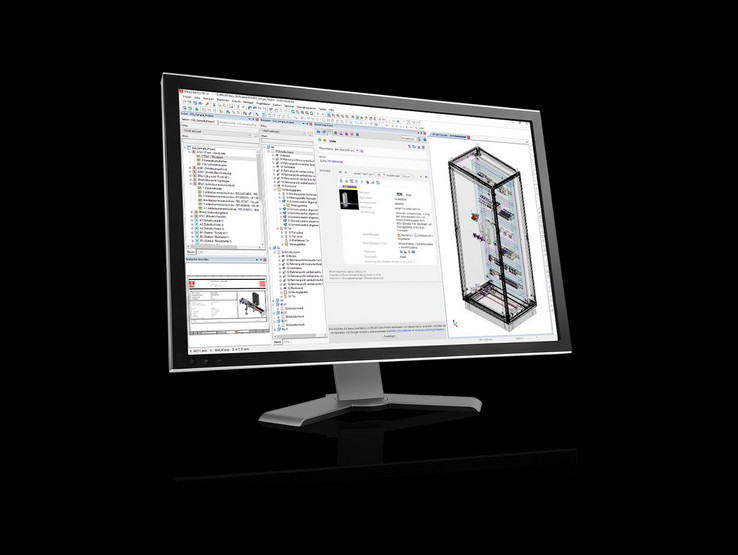

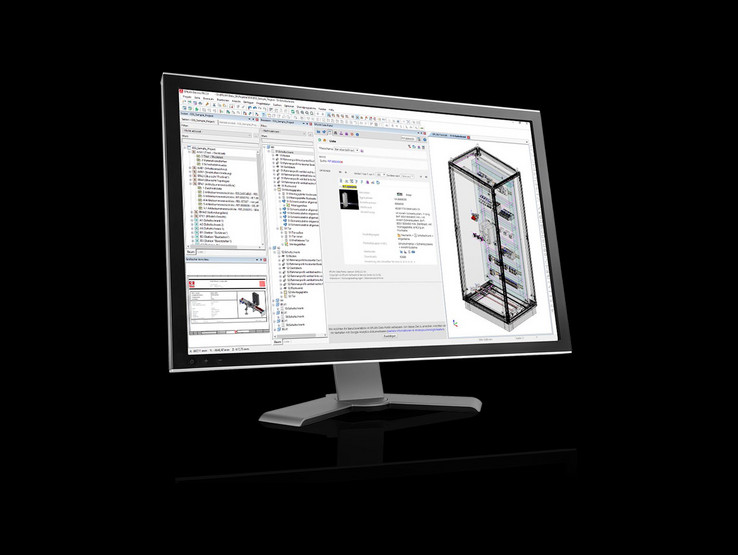

Digital Twin

The digital twin brings great opportunities concerning manual process steps as well as for automation and digitalization of all process steps in panel building, e.g. mechanical processing, wire prefabrication, wiring and terminal assembling.

EPLAN Pro Panel

- From generating circuit diagrams and assembly layouts to production integration – complete all tasks in a single software package

- By providing order information and comprehensive manufacturing documents, you achieve automated enclosure manufacturing

- You shorten throughput times and costs – at a targeted level of quality

- You work profitably – from an individual project in batch size 1 all the way to volume production

EPLAN Data Portal

- Find standardized and internationally applicable component data quickly and easily

- Benefit from clear time savings during project planning compared to manual processes

- Boost the quality of your documentation significantly

EPLAN eMANAGE

- Central access to your EPLAN project files, master data and further files along the value chain for all project partners

- Ensure that everyone is working with the same version of your project data, whether company employees or external project partners

- Retain full control over your intellectual property

- Exploit synergy effects between different EPLAN solutions by simply forwarding your project data to other applications, e.g. EPLAN eVIEW

Thermal Design & Dimensioning

Customer requirements, ambient conditions at the installation site, electrotechnical components and their power dissipation as well as the defined assembly layout of the digital twin define the framework conditions for configuring and dimensioning the optimal climate control solution and the correct distribution of the air flows.

EPLAN Pro Panel

- From generating circuit diagrams and assembly layouts to production integration – complete all tasks in a single software package

- By providing order information and comprehensive manufacturing documents, you achieve automated enclosure manufacturing

- You shorten throughput times and costs – at a targeted level of quality

- You work profitably – from an individual project in batch size 1 all the way to volume production

Thermal Design Integration

- Avoid planning mistakes thanks to the visualization of hot spots and exclusion zones dictated by ventilation requirements

- Minimize downtimes and reduce the number of service assignments

- Lower costs and improve process quality

RiTherm

- RiTherm takes care of all aspects of complex calculations for climate control requirements

- Benefit from huge time savings and improved reliability

- The calculation produces an optimum climate control solution

EPLAN Data Portal

- Find standardized and internationally applicable component data quickly and easily

- Benefit from clear time savings during project planning compared to manual processes

- Boost the quality of your documentation significantly

EPLAN eMANAGE

- Central access to your EPLAN project files, master data and further files along the value chain for all project partners

- Ensure that everyone is working with the same version of your project data, whether company employees or external project partners

- Retain full control over your intellectual property

- Exploit synergy effects between different EPLAN solutions by simply forwarding your project data to other applications, e.g. EPLAN eVIEW